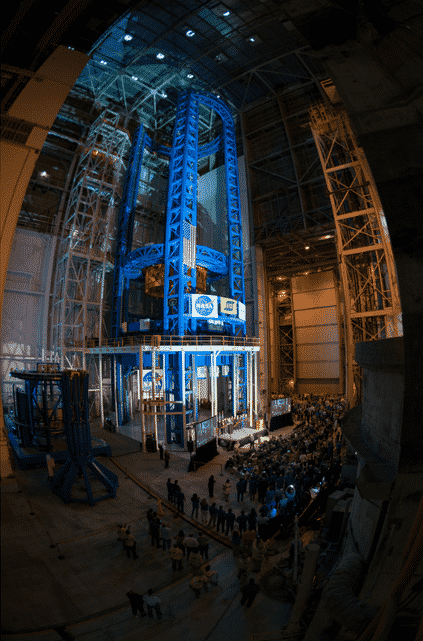

Space agency NASA is preparing itself to build a brand new and the world’s largest rocket called the Space Launch System (SLS) whose sound during launch may annihilate surrounding buildings. And to build this largest rocket, NASA has made the world’s largest spacecraft welding tool and lately, the agency has just unveiled it.

America’s next great rocket SLS is actually a carrier rocket. It will be used to launch crew and cargo into deep space missions in less than three years (by 2017). It will be the most powerful rocket ever built for deep space missions, including catching up an asteroid and landing on it, and eventually getting to the red planet Mars. And to build this largest rocket of the world, NASA has made the world’s largest spacecraft welding tool.

This largest spacecraft welding tool is 170-foot-tall and 78-foot-wide. This world-class welding toolkit will be used to build the core stage of the SLS. The core stage, towering more than 200 feet tall (61 meters) with a diameter of 27.6 feet (8.4 meters), will store cryogenic liquid hydrogen and liquid oxygen that will feed the rocket’s four RS-25 engines.

NASA Administrator Charles Bolden said, “This rocket is a game changer in terms of deep space exploration and will launch NASA astronauts to investigate asteroids and explore the surface of Mars while opening new possibilities for science missions, as well.”

The spacecraft welding tool is set at the Vertical Assembly Center where the core stage of SLS will be designed. This center will join domes, rings and barrels to complete the tanks or dry structure assemblies. It also will be used to perform evaluations on the completed welds.

SLS program manager Todd May said, “The SLS Program continues to make significant progress. The core stage and boosters have both completed critical design review, and NASA recently approved the SLS Program’s progression from formulation to development. This is a major milestone for the program and proof the first new design for SLS is mature enough for production.”

Recently, NASA engineers have completed welding all the rings for the first flight of SLS using the Segmented Ring Tool. Ten barrels also have been welded for the SLS core stage using the Vertical Weld Center. The rings connect and provide stiffness between domes and barrels, which will make-up the five major core stage structures: the forward skirt, the liquid oxygen tank, the intertank, the liquid hydrogen tank and the engine section. Here’s a video of building the backbone of SLS rocket.

Source: NASA

[ttjad keyword=”pc-game”]

![Read more about the article [Video] Amazing View Of Moon Rotating Earth From NASA’s Juno Spaceship](https://thetechjournal.com/wp-content/uploads/2013/12/Earth-And-Moon-Captured-By-Juno-512x299.jpg)