Thinfilm, a Norwegian developer of printable memory has co-announced with California’s Xerox PARC a development that takes a big step towards the day when every manufactured object will report in to the internet and Thinfilm has been producing low-capacity read/write printable memory, which has been used in such applications as personalized toys and games. The resulting integrated circuits are essentially CMOS chips that can be printed on large rolls at extremely low cost and the most obvious application of the technology is in NFC chips, but the small price and size could find the printable circuits turning up as everything from price tags to freshness sensors on food packaging……………….

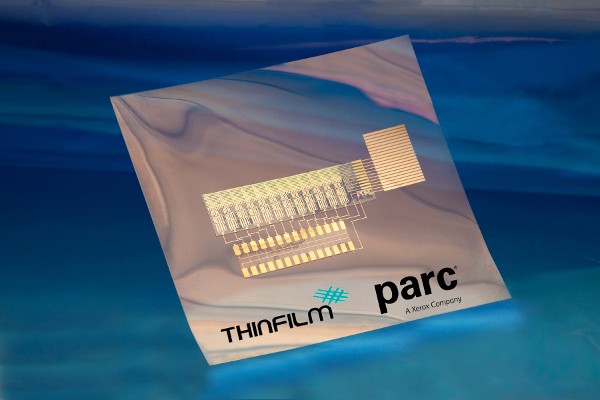

Thin Film Electronics ASA together with PARC, a Xerox company announced they have produced a working prototype of the world’s first printed non-volatile memory device with complementary organic circuits, the organic equivalent of CMOS circuitry. Thinfilm Addressable Memory consists of Thinfilm‘s printed memory and PARC‘s transistors. This demonstration is a significant milestone toward the mass production of low-cost, low-power ubiquitous devices that are a key component of the Internet of things. Thinfilm Addressable Memory combines Thinfilm‘s polymer-based memory technology with PARC‘s transistor technology using complementary pairs of n-type and p-type transistors to construct the circuits. The addition of the integrated circuits makes the roll-to-roll printed Thinfilm Memory addressable by printed logic. The demonstration of Thinfilm‘s Addressable Memory is a significant step toward the vision of a world filled with the Internet of things, where everything is connected via a smart tag. These smart tags require the commercial availability of devices that:

- Have rewritable memory,

- Are low cost,

- Support integration with sensors and other electronic components,

- Are environmentally friendly,

- And can be produced using high volume, roll-to-roll printing

The demonstrated prototype, rewritable memory with logic circuitry, meets all of these requirements. “This milestone is an important step toward a new generation of electronics that will include the prospect of inexpensive memory everywhere,” said Ross Bringans, Vice President, PARC Electronic Materials and Devices Laboratory. “We’re partnering with Thinfilm because they have shown that they can deliver a scalable, commercially viable version of this memory that will change the way people interact with the world.” A leader in delivering innovations in printed electronics, PARC specializes in designing full-featured systems for clients’ applications. These systems will benefit from Thinfilm’s unique non-volatile ferroelectric polymer memory technology because power consumption is negligible and no connection to external power is required to retain information. “We have demonstrated that one can address an array of memory cells using printed logic. This opens up new fields of use, as now addressable memory can be combined with sensors, power sources and antennas to power smart applications,” said Davor Sutija, Thinfilm CEO. “This prototype is a demonstration that low-cost printed integrated systems and the tagging of everyday objects is possible, enabling Thinfilm’s vision of ‘memory everywhere’.” Thinfilm offers low-cost, low-power printed electronics for high-volume consumer applications with two main products: Thinfilm Memory and Thinfilm System products.

Thinfilm memory products include 20-bit Thinfilm Memory in production today for consumer applications, such as toys and games, loyalty cards, info-kiosks and the Thinfilm Addressable Memory under development, available in 2012. System products are integrated systems that combine Thinfilm‘s memory technology with other printed components. The target markets for Thinfilm Addressable Memory system products include NFC (Near Field Communications) tags, now available in Android phones, which enable device to device communication and have been predicted to, one day, be on all new objects. Thinfilm also targets sensor tags and disposable price labels. The addressable memory can be integrated with other printed components, such as antennas and sensors to create fully printed systems for interaction with everyday objects and the Internet of things where the temperature of food and drugs are monitored or retail items are tracked individually rather than by pallet, container or truckload with a simple tap of a NFC enabled phone. “This announcement is a significant step forward for the printed electronics industry,” said Raghu Das, CEO of IDTechEX. “Having both printed memory and printed transistors to address the memory is a fundamental ‘building block’ that has applicability to, and enables an enormous number of applications across a myriad of markets.” Using printing to manufacture electronics minimizes the number of process steps, which in turn, dramatically reduces manufacturing costs and lowers the environmental impact compared to traditional semiconductor processes. Thinfilm devices are thinner than traditional silicon devices and can be produced in form factors as slim as a strand of hair.

[ttjad keyword=”electronic”]