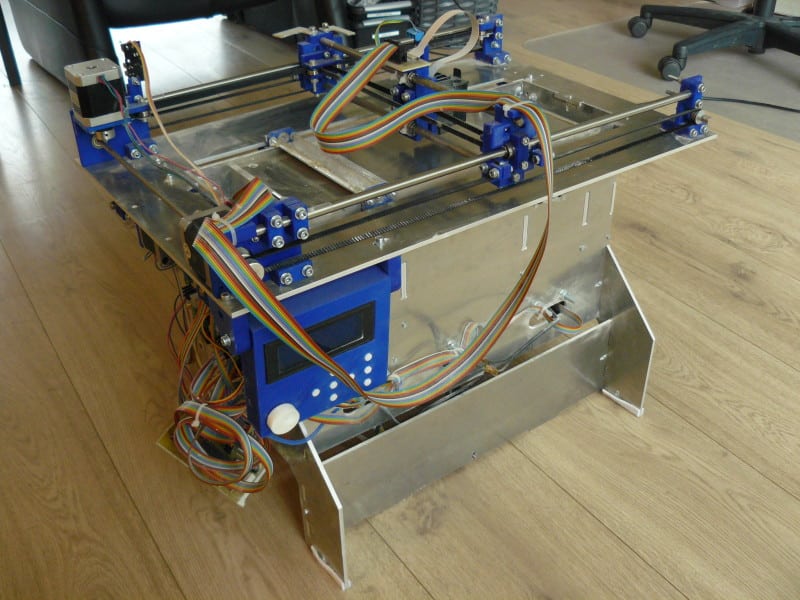

3D printers are becoming very much popular. Every 3D printers, now-a-days, equip new parts and they create some superb 3D models. But, Yvo de Haas has created Plan B, an open source 3D printer that lets people print solid plastic objects by binding a thin layer of plastic powder with an old printer head.

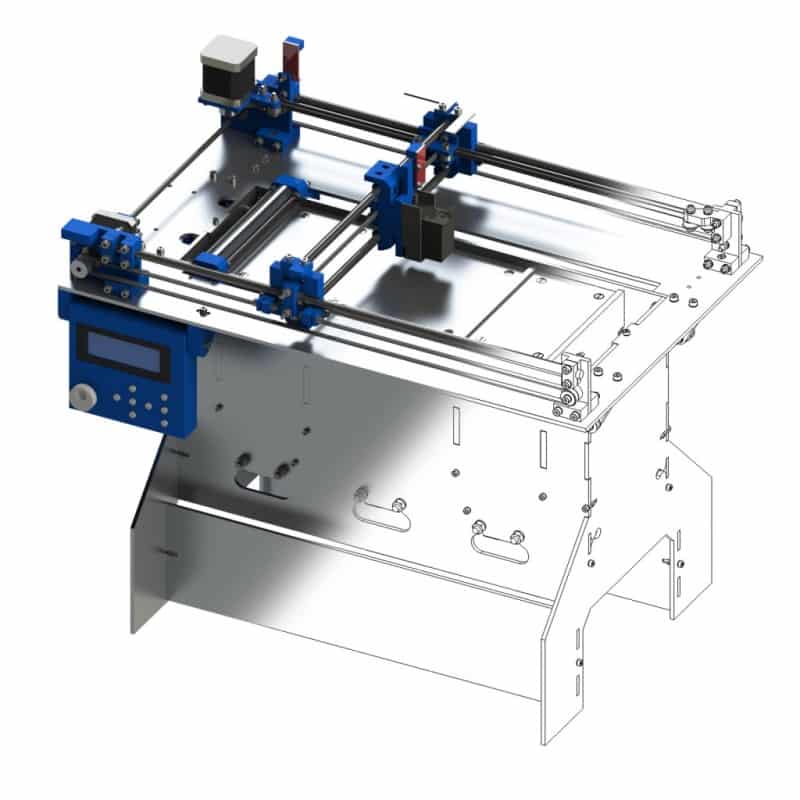

Before proceed further, lets know a bit more about Plan B. Plan B is an open source 3DP 3D printer. It is made with ordinary 3D printer parts, of the shelf inkjet technology and a Laser or Water cut aluminum frame. It has a resolution of 96DPI (roughly 0.26mm per dot). See the specs of Plan B 3D printer at a glance.

Printing

Buildbox dimensions: 150 mm x 150 mm x 100 mm (l x w x h)

Layer thickness: 0.1 mm to 0.25 mm

Inkjet resolution: 96DPI (HP C6602)

Build material: Currently only Zcorp Gypsum and binder without color (this list will expand)

Step accuracy (X/Y): 0.05 mm

Speed: 60 mm/s (higher with future firmware)

Printing speed: Up to 30 mm per hour (higher with future firmware)

Power consumption: Up to 160W (around 90W average)

Construction

Printer dimensions: 550 mm x 350 mm x 450 mm (l x w x h)

Printer weight: 16kg

Frame material: Aluminum and 3D printed plastic

Linear guides: LM8UU on 8 mm steel rods

Number of motors: 6x NEMA17 stepper motors

Features: LCD screen, Keypad with rotary encoder, SD card reader

Now, lets come to the point – 3DP printer. 3DP printer means it uses a little bit of glue to bind thin layers of gypsum powder. The head “draws” the layer in binder and then brushes away the excess. Then another layer of powder is placed and the system repeats itself ad infinitum until the object is built. Here’s a video of the Plan B 3D printer.

The Plan B 3D printer can be built for under $1,000. You can download the build manual from here. For more details about the printer like pros and cons, plans about further development, hit the link below.

Source: YTEC3D

Thanks To: 3Ders

[ttjad keyword=”printers”]