Now a days, many 3D structures are being made with the help of 3D printers. But industrial designer Oluwaseyi Sosanya who is a graduate student from the Royal College of Art (RCA) has created a superb machine that can make flexible 3D structures out of wool and paper.

3D printing is often depicted as a mysterious and seemingly magic process. With the help of 3D printers, world’s hardest Rubik’s Cube can be made, patient’s severely injured face can be reconstructed, ten full-sized houses can be built in a day and many things can be done. And possibly such magical power of 3D printers has inspired Sosanya to create a unique alternative to 3D printers.

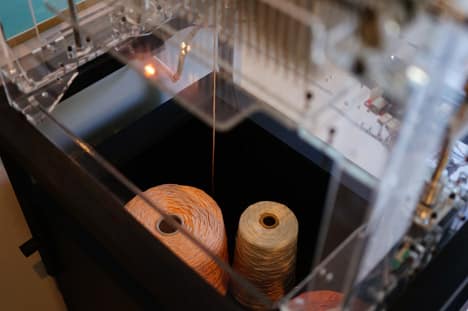

The machine that Sosanya has created can make flexible 3D structures out of wool and paper.

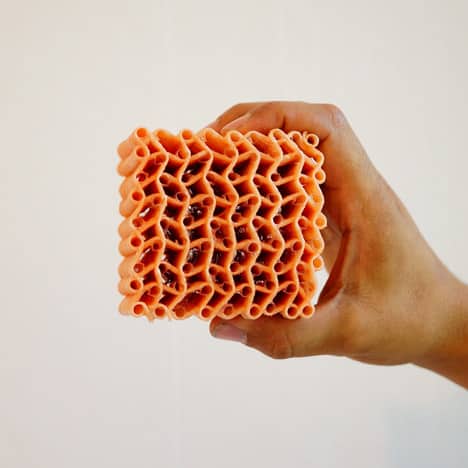

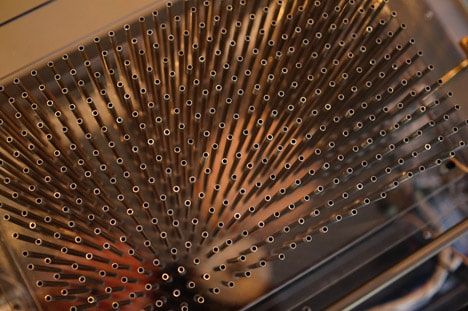

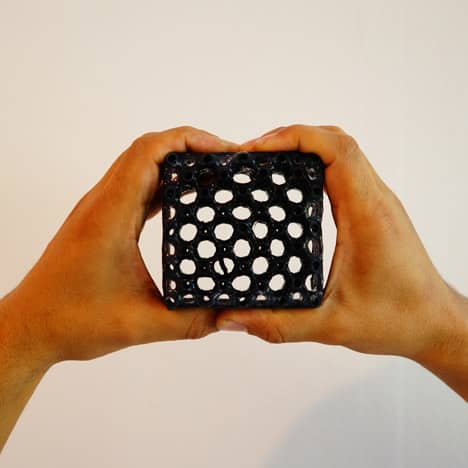

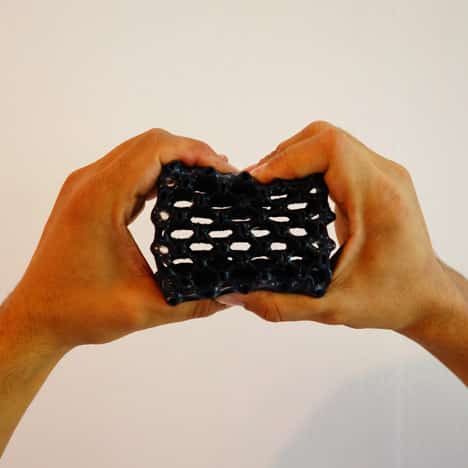

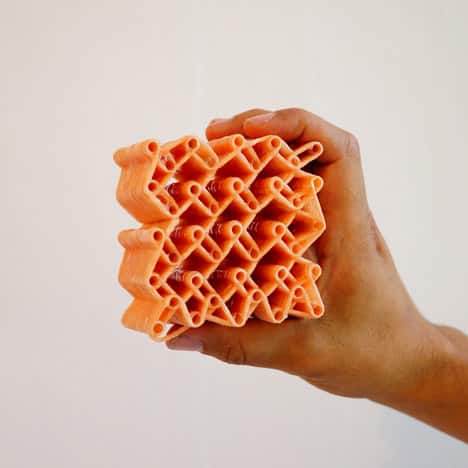

The machine weaves together layers of material at different heights to create 3D shapes.

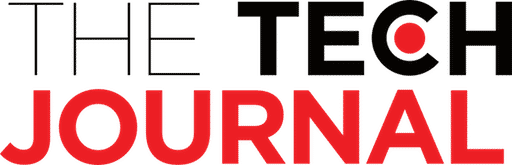

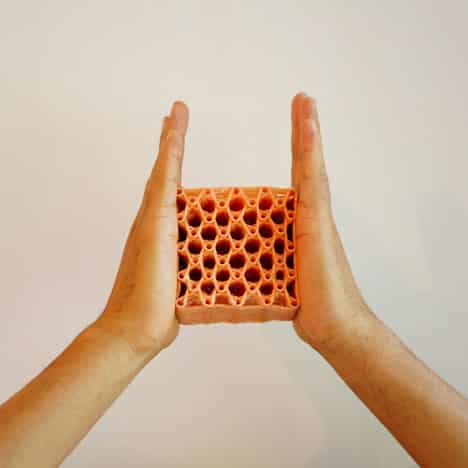

Once the design is woven, it can then be dipped in silicone to make it stronger. The resulting creations are both flexible and strong.

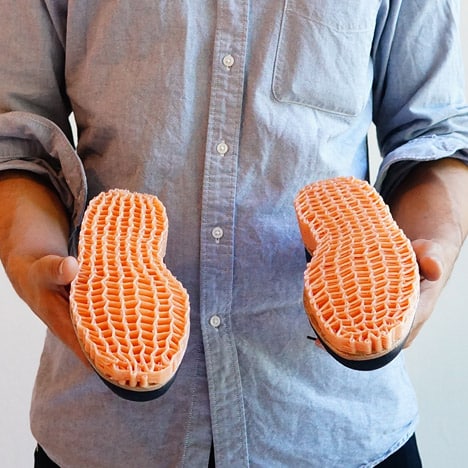

Sosanya has provided an example of a real world application by creating soles for a pair of shoes. The soles were made using a combination of cotton, paper, and wool, and consist of one continuous thread.

Last month, Sonaya displayed his machine at Royal College of Art, London. He believes that the machine can be applied to everything – from medical implants to air purification and much more.

However, currently Sosanya is working on a material that will “address several of the issues caused by body shape that surround stab resistant vests worn by female British law enforcement officers.” There’s no word on when or if it might be available commercially.

Source: Dezeen

Thanks To: The Verge

[ttjad keyword=”printers”]