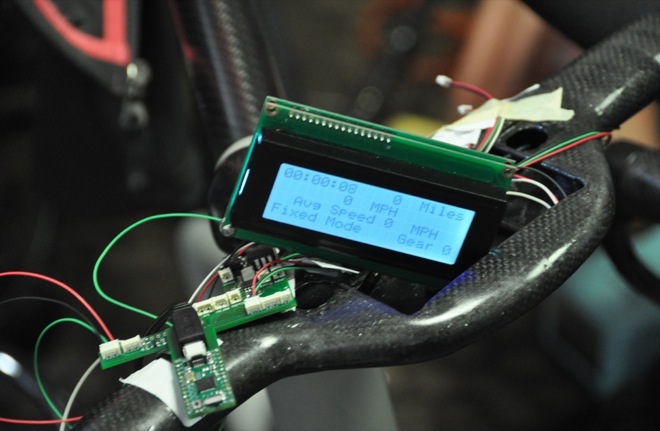

A team of University of Pennsylvania mechanical engineering students have been working on a prototype bike that boasts a bunch of innovations, it’s called ALPHA, is completely enclosed inside the frame and the rear wheel hub contains a three-speed gearbox and also there’s an electronic clutch allowing you to switch between fixed-gear mode and freewheel mode.This bike has an LCD screen mounted on the handlebars to display stats that can be downloaded via a removable SD card………….

The Alpha bike is the product of a year’s work by five mechanical engineering seniors at the University of Pennsylvania and it manages to pack in enough tech to be the KITT of bikes, but with the looks of a stripped-down fixie.Thanks to rapid prototyping technology, the bike was realized almost entirely at UPenn‘s engineering school.Many of the innovations lie in the drivetrain: besides being fully enclosed within the frame, an electronic clutch allows the rider to switch between fixed-gear and freewheel settings.The custom handlebars (track drops) are built into the stem to accommodate a LCD screen, not to mention the internal electronics. the bar-end brake lever is wired to drum brake in the front hub, which also houses a dynamo which generates power for the onboard electronics.The rotation of the front wheel illuminates the integrated rear LEDs and charges two 120 Farad super capacitors.Furthermore, for today’s metric-fixated rider additional data, which can be used to analyze bike dynamics post-ride, is stored on an SD card that is easily accessible from beneath the handlebars.

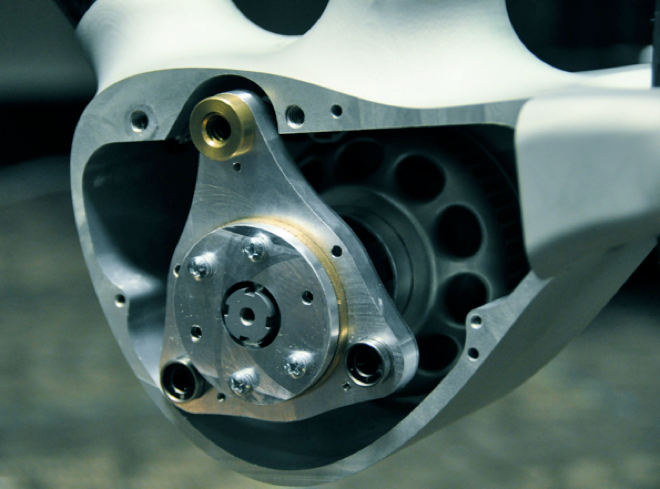

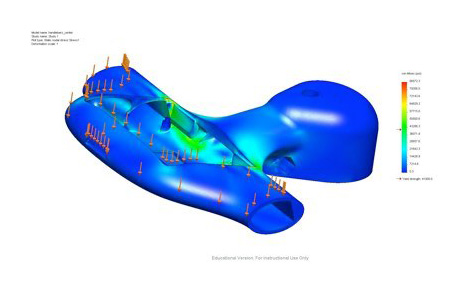

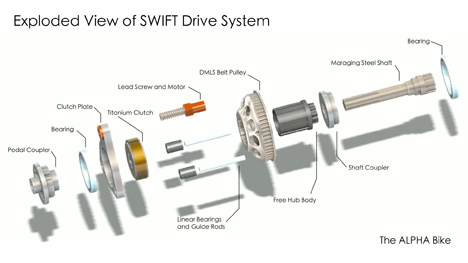

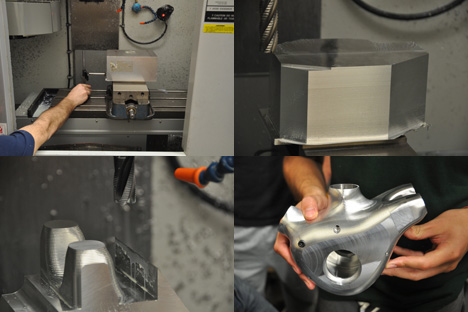

The Switchable Integrated Free-Fixed Transmission uses an electromechanical actuated clutch to switch the bike’s configuration between fixed-gear and free-wheeling modes. Metallurgical considerations played a major role in selecting materials for all of the transmission components.The geometrically complex belt pulleys were made from Stainless Steel using Direct Metal Laser Sintering, a process which allowed us to create otherwise un-machineable parts. Finally, the rear hub incorporates a compact three-speed planetary gear set actuated by a standard push-pull cable.Carbon-fiber tubes, which house internal cables, are joined by aluminum lugs—all produced in-house using CAD, CAM and CNC-machining. The bulbous bottom bracket cluster and fork ends conceal moving parts of the drivetrain, while the belt is hidden inside the right chainstay (as per convention; see video below). The joints were epoxied and cured for five days to ensure structural integrity.Rapid prototyping was paramount to executing the design:3D printing was used to prototype almost every part before design was finalized and final manufacturing began.Finally comes the front brake. This too is minimal and the cable runs through the frame.The Alpha really is a weird machine with those huge lugs, granny hub and high-tech everything.

Alpha: Possibly the Most High-Tech Bike Ever from Core77 on Vimeo.

ScreenShots :

Via

[ttjad keyword=”auto”]