Sumitomo Electric Industries has set up a small-scale production line at its Osaka Works R&D center to produce the battery-boosting material, Aluminum-Celmet and this development is an outgrowth of its previous work on similar nickel and nickel-chromium materials that they branded as Celmet. The resulting Aluminum-Celmet has a whopping 98 percent porosity rate, leaving the Li-ion gate wide-open for a flood of electrical juice and this piece de porous non-resistance has a steep corrosive threshold that could soon help power a line of high-capacity, small form rechargeable batteries…………

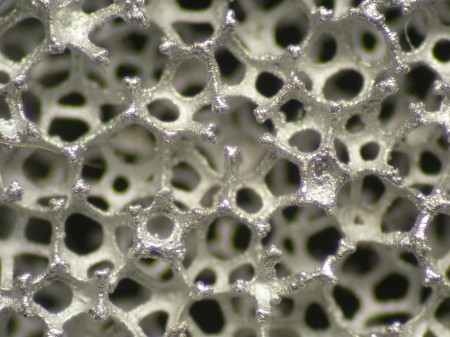

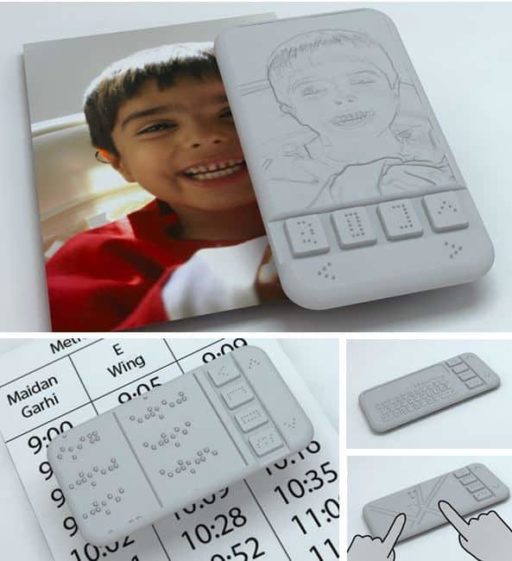

Sumitomo Electric Industries having newly developed its porous aluminum Aluminum-Celmet has set up a small-scale production line at Osaka Works to accelerate development efforts toward mass production of the new material. Aluminum-Celmet (x40)Celmet is a porous metal made from nickel or nickel chrome alloy. The porous metal manufacturing process comprises electro conductive coating to plastic foam, followed by nickel plating and plastic foam removal by heat treatment. Celmet‘s features include high porosity (up to 98%), considerably higher than other porous metals, such as nonwoven metal fabric and foam metal; it also features a three-dimensional mesh-like structure that forms interconnected, open and spherical pores. Moreover, it is easy to process the porous metal into various shapes by cutting and stamping. These features lead to favorable filling, retaining and current-collecting performance, when used with an active material. As such, Celmet has recently been adopted as a positive electrode current collector in hybrid vehicle nickel-hydrogen batteries. In addition to sharing the high porosity feature of Celmet, Aluminum-Celmet offers lightness and greater electrical conductivity.

Aluminum-Celmet offers excellent corrosion resistance. These features make it suitable for use in lithium-ion and other secondary batteries operating at high charge/discharge voltages for which Celmet made from nickel is not suitable. Aluminum-Celmet can also be used for current collectors in capacitors. Aluminum-Celmet can be used to improve the capacity of lithium-ion secondary batteries and capacitors. The positive electrode current collector in a conventional lithium-ion secondary battery is made from aluminum foil, while the negative electrode current collector is made from copper foil. Replacing the aluminum foil with Aluminum-Celmet increases the amount of positive active material per unit area. Sumitomo Electric‘s trial calculations indicate that in the case of automotive onboard battery packs, such replacement will increase battery capacity 1.5 to 3 times. Alternatively, with no change in capacity, battery volume can be reduced to one-third to two-thirds. These changes afford such benefits as reduced footprint of home-use storage batteries for power generated by solar and other natural sources, as well as by fuel cells. In conventional capacitors, both positive and negative current collectors are made from aluminum foil. Use of Aluminum-Celmet instead improves the capacity and reduces the footprint, as with lithium-ion batteries.

[ttjad keyword=”general”]